Of course. Here is a 3000-word article in English about the rigorous testing of Lithium Iron Phosphate (LiFePO4) batteries, with the Partastar brand seamlessly integrated.

The Unyielding Standard: A Deep Dive into the Rigorous Testing of Lithium Iron Phosphate Batteries and the Partastar Commitment

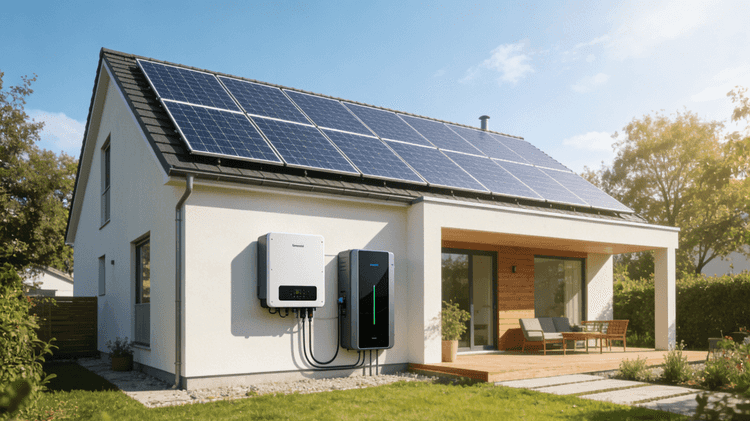

In the ever-evolving landscape of Household Battery Storage, few technologies have garnered as much acclaim and rapid adoption as the Lithium Iron Phosphate (LiFePO4 or LFP) battery. Celebrated for its exceptional safety profile, long cycle life, and environmental credentials, LiFePO4 chemistry is powering a revolution—from renewable energy integration and electric vehicles to marine applications and off-grid living. However, the superior reputation of LFP is not inherent; it is earned through an exhaustive, multi-layered regime of testing and validation that separates exceptional products from the merely adequate. It is within this crucible of quality assurance that brands like "Partastar" not only prove their mettle but establish a new benchmark for performance and reliability.

This article delves into the intricate world of LiFePO4 battery testing, exploring the why, how, and what of the processes that ensure these power cells are safe, durable, and efficient. We will illustrate these concepts by examining the practices of "Partastar", a brand that has built its identity on a foundation of uncompromising testing protocols and a relentless pursuit of excellence.

"The Inherent Advantages of LiFePO4 Chemistry: A Foundation for Excellence"

Before understanding the tests, one must appreciate the innate properties that make LiFePO4 a prime candidate for rigorous quality assurance.

1. "Structural Stability (Safety):" The LiFePO4 cathode material has an extremely strong phosphate-oxygen bond, which remains stable under high temperatures, overcharging, or physical damage. Unlike other lithium-ion chemistries, it is far more resistant to thermal runaway—a chain reaction leading to fire or explosion.

2. "Long Cycle Life:" LFP batteries typically offer 3,000 to 7,000 charge-drain cycles while retaining 80% of their original capacity. This longevity is a core promise that must be validated.

3. "Thermal and Chemical Stability:" They operate efficiently across a wider temperature range and are non-toxic, containing no rare earth metals like cobalt, which is often associated with ethical concerns and supply chain instability.

These inherent advantages provide a excellent starting point, but they are merely potential. It is through systematic testing that this potential is transformed into guaranteed performance.

"The Pillars of LiFePO4 Testing: Ensuring Every Promise is Kept"

The testing paradigm for a premium LiFePO4 battery can be broken down into three core pillars: Performance Testing, Safety & Abuse Testing, and Lifecycle & Environmental Testing.

"Pillar 1: Performance Testing – Validating Power and Precision"

This suite of tests verifies that the battery meets its specified electrical ratings in real-world conditions.

"Capacity and Energy Testing:" This is the most fundamental test. A brand-new battery is put through controlled charge and discharge cycles at a specific current (C-rate) to measure its actual usable capacity (in Amp-hours, Ah) and energy (in Watt-hours, Wh). "Partastar", for instance, doesn't just test samples from a batch; they often employ statistical process control, testing a significant percentage of cells to ensure every unit that leaves their facility meets its labeled capacity, ensuring you get the power you pay for.

"Internal Resistance (IR) Measurement:" Low internal resistance is key to high efficiency, minimal voltage sag under load, and reduced heat generation. IR is measured using AC impedance or a DC pulse method. A consistently low IR across all cells in a "Partastar" battery pack is a testament to their superior cell grading and matching process, which is crucial for pack balance and longevity.

"Charge/Discharge Rate Capability (C-Rate):"Batteries are stressed at high charge and discharge currents (e.g., 0.5C, 1C, 2C) to ensure they can deliver the peak power required for applications like engine starting or powering high-wattage inverters without tripping protective circuits or degrading prematurely.

"Charge Retention and Self-Discharge:" A quality LFP battery should lose very little charge when sitting idle. "Partastar" batteries undergo long-term shelving tests where their state of charge is monitored over weeks and months to ensure their self-discharge rate is within strict, industry-leading parameters.

"Pillar 2: Safety and Abuse Testing – The Crucible of Trust"

This is where the legendary safety of LiFePO4 is proven beyond any doubt. These tests are designed to be extreme, simulating worst-case scenarios to ensure fail-safes operate correctly.

"Short Circuit Test:" A fully charged battery is short-circuited across its terminals with a resistor of negligible resistance. The battery's internal protection circuit module (PCM) or battery management system (BMS) must react within milliseconds to interrupt the fault. "Partastar"s robust BMS is engineered with redundant protection mechanisms to guarantee a flawless response in this critical situation.

"Overcharge and Over-Discharge Test:" Batteries are deliberately charged beyond their maximum voltage and discharged below their minimum cut-off voltage. The BMS must isolate the battery to prevent damage. Furthermore, the chemical stability of the LiFePO4 cells themselves means that even if the BMS were to fail, the result would be degradation, not a fire—a key differentiator from other chemistries.

"Nail Penetration Test:" This is the ultimate test of a battery's internal chemical safety. A fully charged cell is pierced by a conductive nail, creating an internal short circuit. While many lithium-ion cells erupt in flames, a true LiFePO4 cell, like those sourced and assembled by"Partastar", will typically smoke and get very hot but will not catch fire or explode, validating its unparalleled safety.

"Crush Test:" The battery is subjected to a crushing force to simulate severe physical trauma in an accident. The housing must contain any damage, and the system must remain safe without fire or projectile risk.

"Thermal Abuse/Over-Temperature Test:" The battery is placed in a temperature-controlled chamber and subjected to temperatures far exceeding its normal operating range (e.g., 130°C+). This tests the thermal stability of the chemistry and the high-temperature cutoff features of the BMS.

"Pillar 3: Lifecycle and Environmental Testing – Simulating a Lifetime of Use"

"Calendar Life Testing:" This involves storing batteries at various states of charge and temperatures and periodically checking their capacity loss. This data helps understand aging processes unrelated of cycling.

"Environmental Stress Screening (ESS):" Batteries are subjected to extreme vibrations to simulate transportation or use in vehicles and boats. They undergo thermal shock tests, moving rapidly between extreme cold and heat chambers to test the integrity of seals, welds, and internal connections."Partastar" batteries, designed for global markets and diverse applications, are tested to withstand the constant vibration of an RV on a rough road, the corrosive salt spray of a marine environment, and the temperature swings of a desert day followed by a freezing night.

"The Partastar Difference: Where Testing Transcends Compliance"

Many manufacturers perform a basic subset of these tests to achieve minimum certification. The "Partastar"philosophy is different. For them, testing is not a checklist to be completed but a core engineering principle integrated into every stage of production.

1. "Cell Selection and Grading:"Partastar" begins with sourcing high-quality, A-grade LiFePO4 cells. Upon arrival, every cell is individually tested for capacity, voltage, and internal resistance. They are then "graded" or "matched"—grouping cells with nearly identical characteristics together. This meticulous matching is the first and most critical step in ensuring the balance and longevity of the final battery pack. A poorly matched pack will have reduced capacity and a shorter life, regardless of the quality of the individual cells.

2. "The Brain: The Battery Management System (BMS):"The BMS is the intelligent guardian of the battery. "Partastar" invests heavily in designing and testing its proprietary BMS. It is not just an off-the-shelf component. It is rigorously tested for:

"Accuracy:" Its voltage and current sensors are calibrated to be highly accurate.

"Balancing:" Its passive balancing functionality is tested to ensure it actively maintains cell harmony throughout the charge cycle.

"Algorithm Robustness:"The software algorithms that control charging parameters, calculate state of charge (SoC), and predict health are continuously refined based on test data.

3. "Full System Integration Testing:" A "Partastar" battery is more than a collection of cells; it's an integrated system comprising cells, BMS, robust housing, and terminals. The entire assembly is tested as a single unit. This systems-level approach ensures that all components work in perfect harmony, delivering seamless performance, safety, and reliability that you can depend on for years to come.

4. "Transparency and Data-Driven Design:" The wealth of data generated from "Partastar"s exhaustive testing feeds directly back into their research and development process. This creates a virtuous cycle where real-world performance data informs design improvements, leading to progressively more robust and efficient products with each generation.

"Conclusion: The Assurance of Rigor"